41 how to label warehouse racking

Used Metal Shelving for Sale by American Surplus Inc. WebFor warehouses facilities with high storage demands, used warehouse shelving is a cost-effective solution. It significantly influences revenue and will provide you with the additional room needed without breaking the budget. Another great advantage of used industrial warehouse shelving is that it is very customizable. Retail News and Ecommerce Market Research I Digital Commerce 360 Web21.12.2022 · Digital Commerce 360 offers daily news and expert analysis on retail ecommerce as well as data on the top retailers in the world.

Microsoft is building an Xbox mobile gaming store to take on … Web19.10.2022 · Microsoft’s Activision Blizzard deal is key to the company’s mobile gaming efforts. Microsoft is quietly building a mobile Xbox store that will rely on Activision and King games.

How to label warehouse racking

A Guide to Labelling Warehouse Racks - rslni.com The first step to effective warehouse labelling is an identification system. Once all of your stock and equipment has been organised and put into its rightful place, code labels can be used to identify items clearly in order to minimise time loss and costly errors to your business. Rack Labels for Warehouses - The Label Experts Warehouse Rack Label Materials. Material. Product Description. 671. White gloss plastic is designed for indoor applications and limited outdoor use. General purpose, aggressive permanent adhesive and works on most substrates including glass, metal, paint and polycarbonate, but testing is always recommended. View Spec Sheet. How to Label a Warehouse Rack - Camcode If the latter sounds like an organizational model that your operation uses, be sure to assign unique identification attributes to each section of each rack, not the entire racking unit itself. Label Your Racks from the Bottom Up This practice is especially relevant to those working with a high-density racking solution that contains multiple levels.

How to label warehouse racking. How To Calculate Warehouse Storage Capacity | T.P. Supply Web28.08.2019 · Calculating your warehouse space utilization will help you make sure you’re as efficient as possible with the available space at your facility. This number represents the percentage of your usable storage space that you’re using. Believe it or not, you don’t want this number to be a perfect 100% — in fact, you want it to be much lower than that. We’ll … Music News - Billboard WebA daily briefing on what matters in the music industry Send us a tip using our anonymous form. A daily briefing on what matters in the music industry Send us a tip using our anonymous form ... › blog › types-of-warehouse-storage6 Types of Warehouse Storage Systems - Camcode Mar 01, 2022 · Warehouse Rack Labels Durable, fully customized label options for every warehouse rack system, including long-range scanning. Warehouse Floor Label Kits The most durable bar code labeling solutions available, with permenant adhesive or mechanical attachment options. Warehouse Racking - Structural Steel Pallet Racking Manufacturers WebOur industrial racking systems are fully designed with convenience in mind, and our structural steel components mean that your storage racking system will be constructed for the greatest durability. Frazier's racking systems are designed to increase the flow and productivity of your warehouse, giving you the ability to store and retrieve your products …

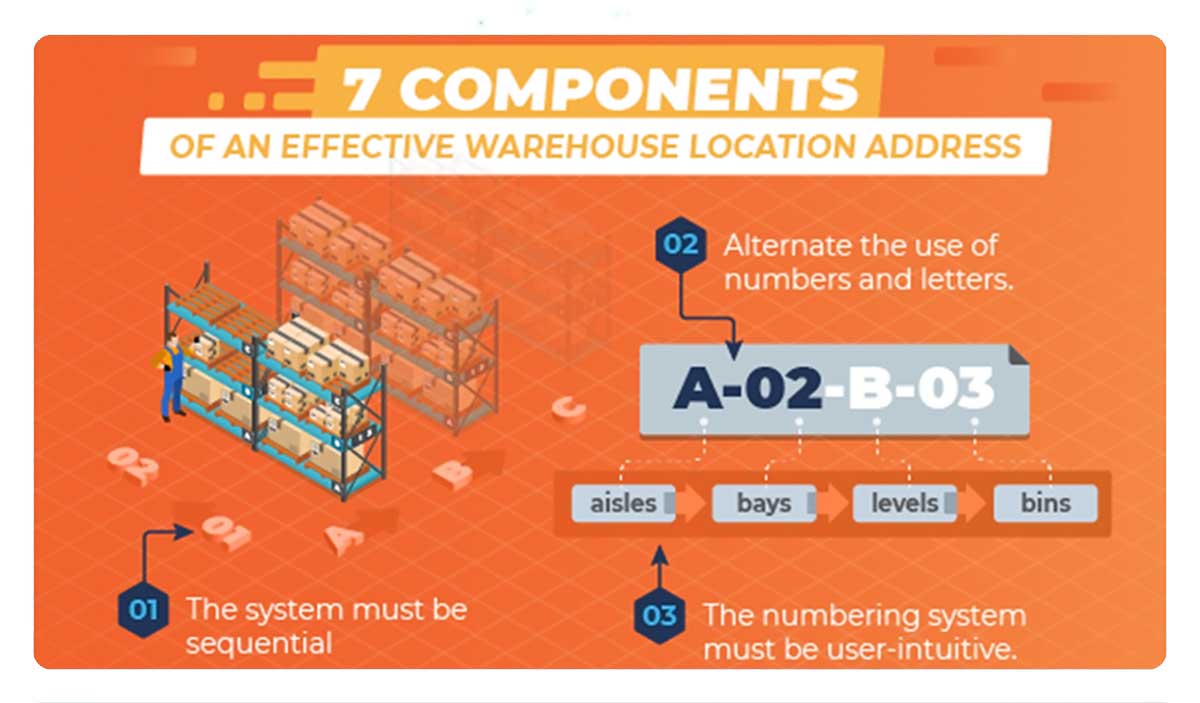

Naming and labelling warehouse bins and shelves - Datalinx Blog Labelling pallet racking and shelves is generally best carried out by the racking specialist suppliers who can provide solutions that use labels that are permanent; not easily damaged and possibly colour coded to identify the racking tier levels etc. Share EU Falsified Medicines Directive 2018 10 minutes with James Pearcy Label Source | News | Shelve It: How to Label Warehouse Racking This allows vertical expansion of racking, without the need to re-label all shelves. For all numbers less than ten it is recommended that zero is added before the number, i.e. 01, 02, 03 etc. This will allow locations to be located alphanumerically. If the warehouse is vast and exceeds 99 aisles, then numbering needs to start at 001 rather than 01. Warehouse Rack Labels and Inventory Labeling Solutions - Camcode With the ability to scan a rack label to document the date, time, and location of an activity, warehouse rack labels virtually eliminate the errors that commonly result from manual record-keeping processes. Armed with accurate data, you'll experience less errors that can result in supply chain delays, such as backorders or incorrect shipments. › internet-retailerRetail News and Ecommerce Market Research I Digital Commerce 360 Dec 21, 2022 · Digital Commerce 360 offers daily news and expert analysis on retail ecommerce as well as data on the top retailers in the world.

What Are The Ways to Label Bin and Rack Locations? | SOLUM It woud be best to map and segment your warehouse and assign specific location names for each of these segments Establish a Bin and Rack Numbering and Labeling Scheme Each aisle, rack, shelf or position should have a specific location code and should be properly labeled based on this location code. What is Warehouse Operations? - Camcode Web28.02.2022 · Maintaining the warehouse facility; Developing racking designs and warehouse infrastructure; Of course, the aforementioned points represent just a fraction of what many modern warehouse operations managers face. That said, they constitute the fundamentals of warehousing, elements that serve as the building blocks for all … Racking Labels - Warehouse Solutions Group If you need something other than standard racking and shelf labels, Warehouse Solutions Group can also produce specialised labels and custom signage, as well as a full sweet of products needed for warehouse Health & Safety compliance. aisle markers label holders warehouse floor labels magnetic labels load notices safety signage More About Us Read This Before Creating a Warehouse Location Numbering Scheme - ScanForce If you have more than 9 levels you should start with 01. Position - assign numbers to each position ascending from 1 to 9, from left to right as you face the rack. Here's an example of a location label where the format is Aisle - Rack - Level - Position. In this case, Aisle 01, Rack 02, Level 1, Position 1. Keep it short and sweet.

Warehouse Racking Safety Guidelines: Satisfying OSHA The iGPS plastic pallet is able to hold heavier static and dynamic loads than a reusable wood block pallet and is equipped with GS1-compliant tracking. To get started with a durable, heavy-duty plastic pallet, give our team a call at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page. By iGPS

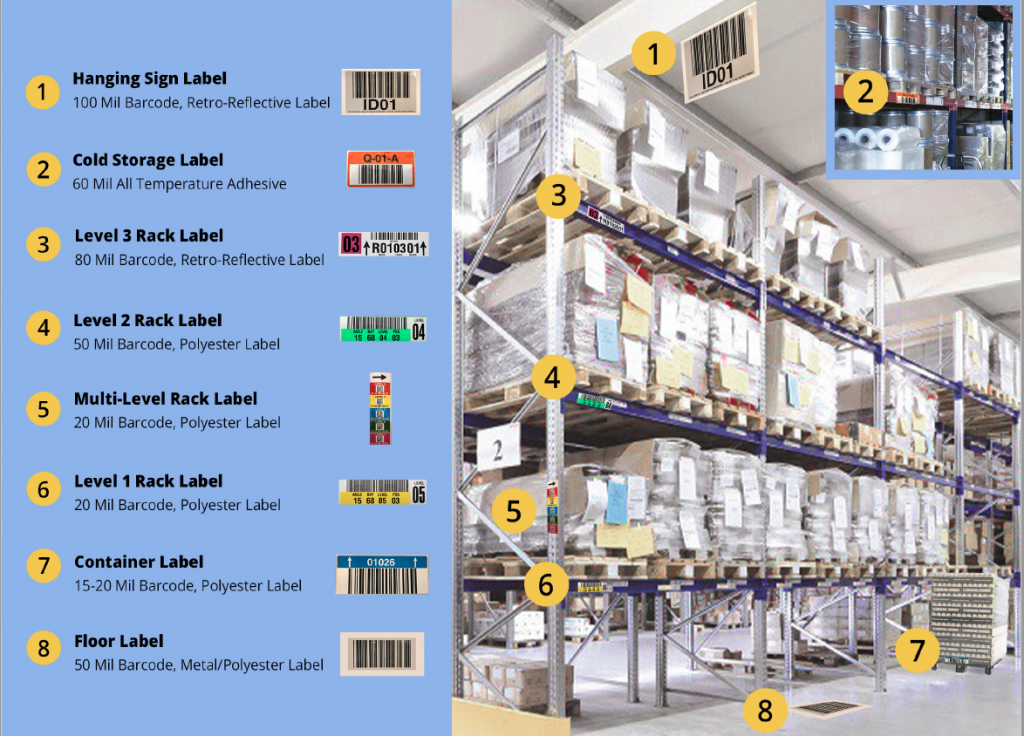

Rack Labels - Imprint Enterprises Imprint has all your rack labels, bin labels, and shelf labels and installation services. We specialize in retro-reflective hanging signs, warehouse rack labels, warehouse bin labels, warehouse shelf labels, sequential pallet license plates, serialized labeling, and much more. (855) 745-4464 customer_service@imprint-e.com.

Warehouse Locations and Bin Labeling: Best Practices and Tips - SkuVault Typically, it is the most specific a warehouse location can get. The next level of location naming is by shelf (AKA row). This is categorized as the horizontal space spanning across a rack. Racks (AKA units or section) can be thought of as large sections of shelving units that store your product.

Daily gaming news - Xfire Web22.12.2022 · Xfire video game news covers all the biggest daily gaming headlines.

Pallet Rack Capacity Labels & Their Importance - SRS-I A typical label should feature the following: Aisle numbering or equivalent identifying code. Minimum area 50 square inches (e.g., 10" x 5"). Clear, legible print (e.g., white or yellow background, standard sans serif font, black text). Maximum permissible load for each pallet or unit OR maximum uniformly distributed load per level.

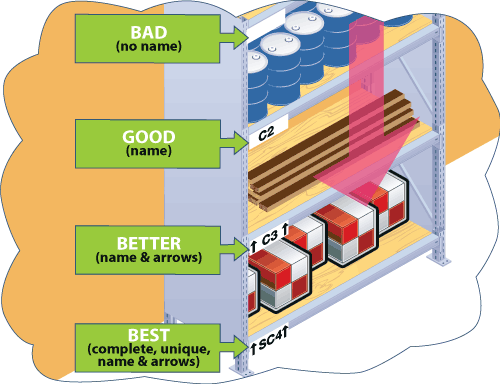

Racking Systems Warehouse Rack Labeling Ideas - Multiplicites Rack labeling is the term for marking aisles and shelves with labels that display logical identification numbers. Perhaps for aisle positions in the shop and warehouse areas. Rack labels are used by our customers in warehouse and distribution operations to help identify pallet locations on racking. When creating a numbering system there are ...

Using Minimum Warehouse Aisle Widths to Maximize Space Web23.04.2019 · That is why the very narrow aisle warehouse layout concept has gained in popularity. It makes sense to reduce your warehouse aisle widths to free up more useable floor and vertical space. Warehouse designers work with these three aisle concepts and widths. Wide aisle design: This is the typical warehouse design that’s been around for …

Common Types of Warehouse Rack Labels - Informs Inc. Warehouse Rack Beam Labels. These are the labels you will most commonly find on warehouse racks. They mark each bay location, and typically use 2D barcodes for scanning. They may also have letters and numbers for workers to identify contents without scanning. These warehouse rack labels are usually made of polyester or a similar material to ...

How To Label Warehouse Racks | inotec In instances of gravity-fed racking, inotec recommends placing a label at both the front and the back of the racking to serve the restocking and retrieving of products. Shelf Labels Shelf labels are a simple yet popular choice for smaller warehouses. They are commonly used for smaller volumes of racking with a basic shelf layout scheme.

Used Conveyors for Sale by American Surplus Inc. WebAs you can see, there are many different ways to utilize the various types of conveyor in your warehouse facility. The amount of options you have may seem overwhelming, but ASI has over 30 years of experience providing material handling solutions for our clients. Our sales team will work with you to determine the proper types of conveyor system for your …

How to Label a Warehouse Rack - Camcode If the latter sounds like an organizational model that your operation uses, be sure to assign unique identification attributes to each section of each rack, not the entire racking unit itself. Label Your Racks from the Bottom Up This practice is especially relevant to those working with a high-density racking solution that contains multiple levels.

Rack Labels for Warehouses - The Label Experts Warehouse Rack Label Materials. Material. Product Description. 671. White gloss plastic is designed for indoor applications and limited outdoor use. General purpose, aggressive permanent adhesive and works on most substrates including glass, metal, paint and polycarbonate, but testing is always recommended. View Spec Sheet.

A Guide to Labelling Warehouse Racks - rslni.com The first step to effective warehouse labelling is an identification system. Once all of your stock and equipment has been organised and put into its rightful place, code labels can be used to identify items clearly in order to minimise time loss and costly errors to your business.

Komentar

Posting Komentar